Mycotoxins are toxic secondary molecules produced by molds. These molecules can cause a wide range of effects depending on the molecular family, combination of contaminants and rearing environment. They occur differently in each part of the world, according to climate and agricultural practices.

Aflatoxins, Ochratoxins, Fumonisins, Zearalenones and Trichothecenes (DON, T2, H-T2, etc.) are the 5 main identified mycotoxins families causing a lot of zootechnical issues with or without clinical effects.

Mycotoxins contamination can occur in the field with molds such as the Fusarium species, producing mycotoxins such as Fumonisins, Trichothecenes and Zearalenones on the crops. Contamination can also happen in storage with fungi, such as the Aspergillus and Penicillium. Those fungi are linked to Aflatoxins and Ochratoxins. One mycotoxin can be produced by several molds and one mold can produce several mycotoxins, causing multiple contamination. Nowadays, nearly all samples that have a positive result for mycotoxin presence are in this situation

Evaluation of the contamination

Raw materials analysis is the starting point of mycotoxins contamination knowledge in each particular situation. Corn, barley, wheat and oats are important substrates, but they are not the only raw materials that need to be analyzed. For ruminants, forages are the main source of contamination which also need to be analyzed.

Mycotoxins contamination can be suspected by molds presence or fermented grains. But in most cases, contamination cannot be suspected and detected by visual inspection, even at high levels. Sometimes, there is no particular alteration of the external aspect, no smell, no taste, no insects. No physical sign of contamination does not mean any contamination at all. Even good-looking raw materials can have a higher contamination level than bad looking ones. Only analysis can confirm the presence of mycotoxins.

To have a representative analysis, you need to have the right sample. The main challenge is to collect a representative sample of your feed knowing that these molecules have a heterogeneous mode of distribution. That is why it is crucial to use the proper sampling method to have a representative sample for analysis. Specific methodologies are developed per type of raw materials and types of delivery. In addition, mycotoxins are very stable and resistant metabolites. They are resistant to thermic treatments up to 250°C (such as extrusion, pelletizing, flacking etc.), physical and chemical treatments (such as cleaning, ammoniac), fermentation, molds inhibitor during storage (such as organic acids which destroy only fungus and not the mycotoxins) and time (even long storage periods).

In turn, these toxic molecules represent a threat for animal species as much as for humans because they compromise animals’ immune systems and food safety. To avoid their negative impacts on animals’ performance, they need to be protected by global insurance linking personalized raw materials control plan services and efficient product solutions.

Toxicity of mycotoxins

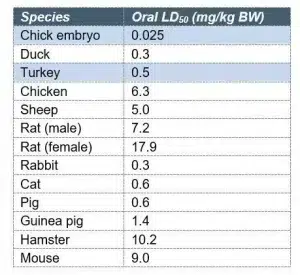

Multiple contaminations in feed increase the toxic effect of mycotoxins and their impact on animals’ performances. With this kind of toxins, both additive and synergic effects are possible, depending on many factors. Not all mycotoxins are equal, nor their impact on animals. Different species, different ages and most importantly different stages of production have different levels of tolerance on different mycotoxins and this is usually where we are taking “the part for the whole” and first start to misevaluate the real mycotoxin risk. Everybody knows that birds are sensitive to aflatoxin, but it is completely different to assess the aflatoxin risk when you are dealing with broiler production or dealing with turkeys or breeders. What can be a tolerant concentration for broiler chicken might be mortal to a turkey or to a chick embryo (Table 1).

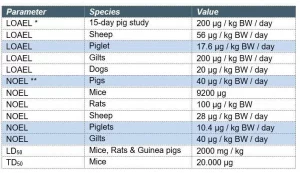

The same stands for the tolerance of zearalenone when we are talking about gilts compared with the young piglets. The tolerance to zearalenone increases with the age, maturity and weight of the pigs as we can see in Table 2.

Source : D.Dhanasekaran et al., 2011

LOAEL: Lowest Observed Adverse Effect Level

NOEL: No Observed Effects Level

Source: Adapted from K. Ropejko and M. Twaruzek, 2021

Zearalenone effects start to be seen at concentration levels of > 10.4 µ/kg of BW/day (or 10.4 ppb) in young piglets whereas in gilts and pigs the NOEL elevates to > 40 µ/kg of BW/day, showing that gilts and pigs are roughly 4 times more resistant to zearalenone than piglets. For piglets, the LOAEL is > 17.3 µ/kg of BW/day, which means significant biological adverse effects start occurring and typical ZEN clinical signs are expected. This is a remarkable fact when you choose a toxin binder and dosage according to the species. On monogastric species, we mainly identified impacts on growth performances, reproduction, metabolism and immunity. On ruminants, we identified impacts on reproduction, milk production but also on milk quality.

Risk identification and monitoring

Multiple contaminations in feed increase the toxic effect of mycotoxins and their impact on animals’ performances. With this kind of toxins, both additive and synergic effects are possible, depending on many factors. Not all mycotoxins are equal, nor their impact on animals. Different species, different ages and most importantly different stages of production have different levels of tolerance on different mycotoxins and this is usually where we are taking “the part for the whole” and first start to misevaluate the real mycotoxin risk.

Everybody knows that birds are sensitive to aflatoxin, but it is completely different to assess the aflatoxin risk when you are dealing with broiler production or dealing with turkeys or breeders. What can be a tolerant concentration for broiler chicken might be mortal to a turkey or to a chick embryo (Table 1).In mycotoxins risk management, prevention is the key point for success.

Indeed, it is critical for feed producers to know the contamination levels and the associated risk by specie, to be able to have a preventive approach. For that, ADM helps customers to build their mycotoxins control plan and offers analysis solutions depending on their situations and objectives.

Having analysis results is the first step of the preventive approach, and to go further ADM developed Mycowatch® app. The monitoring tool allows valorizing mycotoxins analysis results in order to evaluate the contamination risk (from low to critical), to select the most suitable T5X (ADM myGocotoxins solutions) to use depending on the situation and to know the precise dose to use.

This is really a cutting-edge approach due to the big data compilation on T5X dose/effect curves and the addition of a new risk assessment variable (not only by specie but especially) stage of production. This allows the users to have an adequate and efficient usage of T5X in all growing/production stages, avoiding extra costs to the end user as there will be no under or over usage of toxin binder.

Mycowatch® app is available Google Play and Apple stores. The app is mainly dedicated to nutritionists and feed formulators usable for their day-to-day work, in addition, a full report of each simulation can be sent by e-mail for archives.